Five Lessons from Walmart’s Strategic Network Design Talk for my Students

Walmart gave a great talk on strategic supply chain network optimization at the 2024 INFORMS conference.

This post is for my students. And, if I look in the mirror, for me too. Walmart’s talk was pure confirmation bias for me, showing that I’m teaching the right things if the world’s largest (?) supply chain uses these techniques.

I’m now teaching two classes using our Supply Chain Network Design book. One class is a supply chain class for upperclassman IE’s. In that class we focus on supply chain engineering concepts. The other class is for master’s students in machine learning. In that class, we use network design as an excuse to talk about optimization.

Here are the lessons:

One, the book helps you understand real-world network design

Walmart is redesigning its ambient (room temperature) supply chain. They are determining the long-term strategy for replacing two types of warehouses (manual RDCs and High Velocity DCs) with new automated facilities that can handle all products.

This is a classic network design model covered by the models in Chapters 9 and 10— locating the optimal number and location of warehouses with multiple products. (Of course, Walmart has many more constraints and variables, but those models will allow you to understand those.).

Two, it is a good practice to have a model feed other models

Once Walmart has determined the long-term strategy (the number, location, and size of the automated warehouses) for the ambient network, they fed that solution into another model that helped them determine how to get from today’s supply to that one.

In Chapter 4 of the book, we have an example of one model feeding another. I think this isn’t so intuitive when you first see it: why not build one model? I use this model in class to show how this is done, talk about the fact that many real-world problems do this, and use this to set up a discussion of hierarchical and multi-objective optimization.

Walmart took the solution for the long-term strategy and added time periods and many other decision variables and constraints to ensure a smooth transition from today’s supply chain to the new one. In their case, the models are too large to solve as one anyway. But even if they were, you could make a case that a second model is still needed because of the different decisions.

Three, simple models (or simple objectives) are still valuable

In the eCommerce models, Walmart discussed some models that optimized based on distance. These models helped narrow down possibilities for other models.

Our book starts with very simple models. I like to stress that these simple models can be powerful in practice. I worry that the models look too simple. It was good to see Walmart using simple models (or simple objectives).

Four, Mixed Integer Programs (MIPs) are powerful for a range of problems

Walmart’s talk covered five different types of problems they were solving, often with multiple models for each. Walmart talked about MIPs for

Traditional network design and transition planning (ambient network)

eCommerce product flow (how to get products from warehouses to the consumer’s home)

Reducing empty miles from 50% to 33% (the supply chain class may touch on this topic later in the quarter).

Vehicle routing for home delivery options from stores (the optimization class is covering this topic now. I don’t remember, but this might have been light on MIPs).

Affinity planning to make sure the right products are stored together to minimize the number of boxes shipped per order. (There is some good machine learning in this one, too).

MIPs are a workhorse tool. I love that this is a core IE skill and that our machine-learning students know about it, too.

Five, piecewise linear functions can get you out of a pinch.

We cover piecewise linear functions in an early class. This is to help students see that there are some ways to approximate non-linear patterns with linear equations that work for MIPs.

In Walmart’s case, the eCommerce model has different costs depending on the volume of a lane. Here is a picture and equation of that:

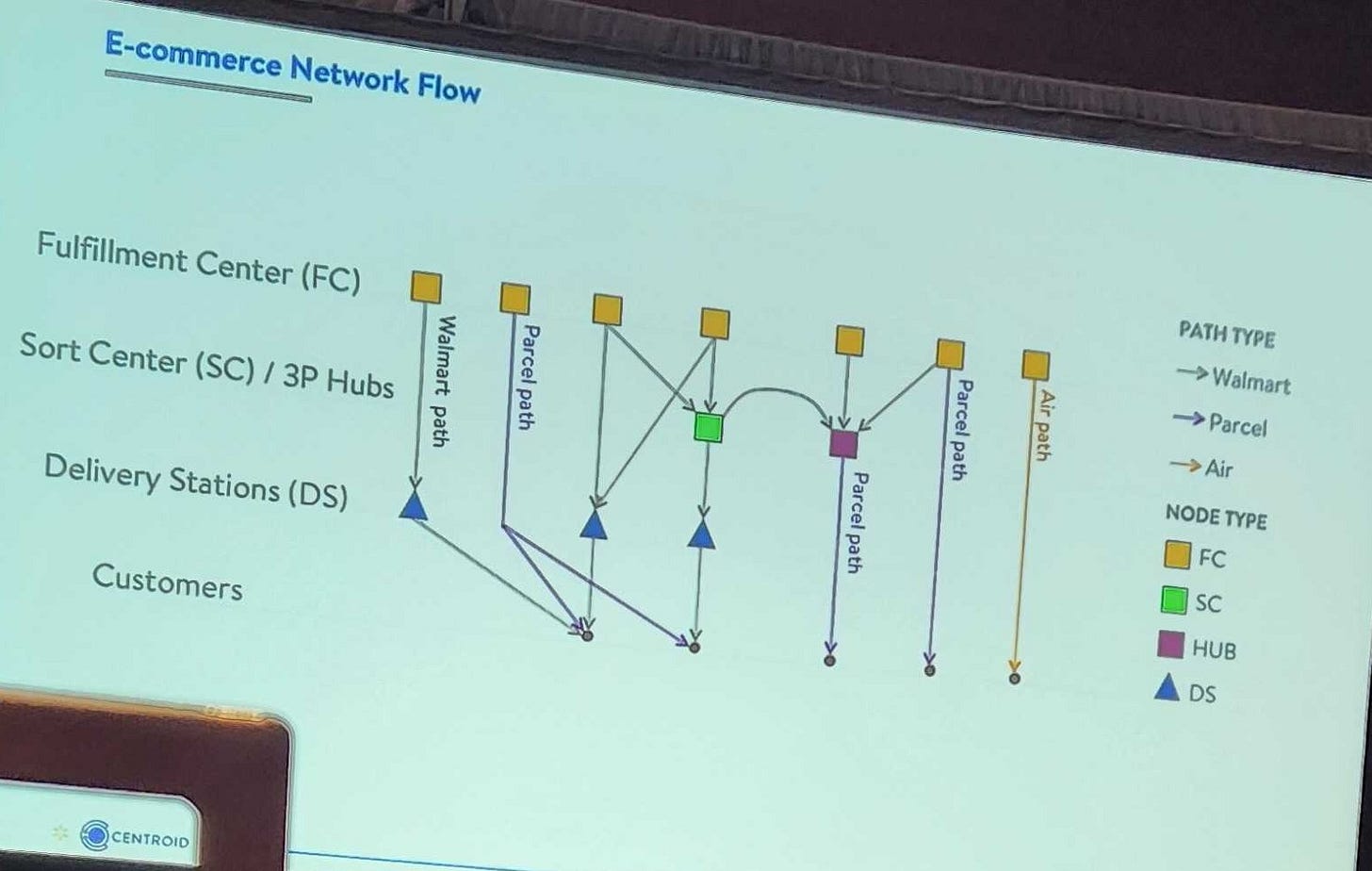

Another way to look at this is through the different paths product can take. The equations above look for ways to consolidate more shipments on specific lanes for a discount. You can see the options below:

If you want more detail, check out Walmart’s talk on their innovative approach to network design. This work won the INFORMS Edelman Prize.